VJ TECHNOLOGIES, We are a leading global supplier of X-ray testing solutions. We apply our expertise in X-ray digital imaging technology to government agencies and the non-destructive testing (NDT) market worldwide. VJT is committed to developing and manufacturing complete automated, manual, and turnkey X-ray detection systems, with main market areas including aviation, automotive, electronics, nuclear waste disposal, oil and gas, as well as pipeline and welding applications. The VJT X-ray testing system provides comprehensive testing solutions for various products and components, helping customers reduce costs, save time, and improve product quality and safety. VJT provides more than just fully customized solutions. VJT also offers a fully customizable standard product that can be quickly implemented and save you costs.

Impressive high-performance Heitec robot wheel detection equipment

The Heitec robot wheel detection equipment has achieved extremely high production capacity with its industrial robots, making it very suitable for online operation of large-scale production of cast aluminum wheels. By using larger detectors, several areas of the hub can be tested at one testing location. This benefit means that the number of operational steps can be reduced, thereby shortening the testing time for each wheel hub.

The Heitec robot wheel detection device is a fully automatic wheel detection device that integrates ISAR image evaluation software and the XEye detector developed by Fraunhofer to achieve almost no false positives and stable image quality.

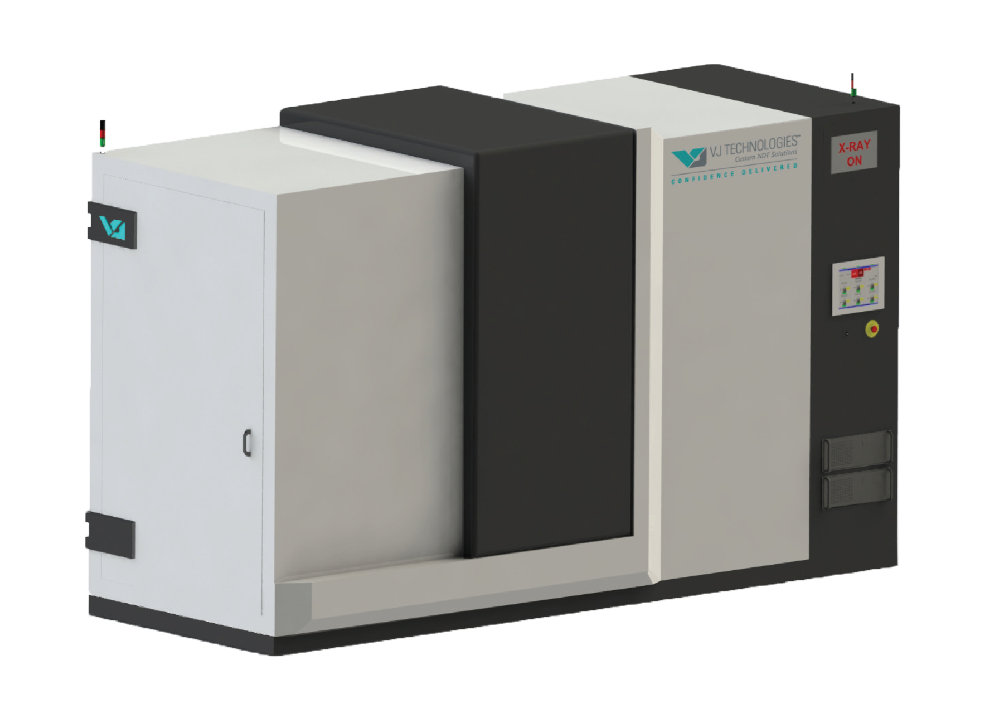

VedaCT is the latest CT series product designed by the company, which can provide a range of radiation from 160KV to 450KV. Users can configure conventional focal point radiation sources and micro focal point radiation sources, and the image receiver can be configured with area array detectors and line array detectors. Provide the latest VG Studio MAX 3D analysis software in terms of software.

The system adopts an integrated lead room design, with a beautiful and elegant overall structure, and the size of the system can be customized according to user needs.

You will experience:

Coordinate measurement, design/actual product comparison, product wall thickness analysis, product porosity/inclusion analysis, fiber composite analysis, mechanical transmission phenomenon simulation, foam structure analysis, structural mechanics simulation.

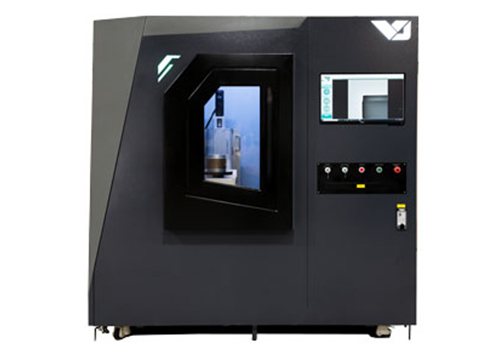

Valu CT, as an entry-level CT system, adheres to VJT's consistent product performance and quality, and incorporates the appearance design of the Golden Ratio.

The device has a small footprint and multiple application functions of DR and CT. The human-computer interaction of the operating software is friendly and convenient, and after short-term training, one can proficiently master the detection methods. The device is small and simple, but powerful, and can be configured with exclusive Vi3 software and VG Studio Max analysis software through the series.

InlineCT has a tube voltage of up to 450kV and a beat time of less than 60 seconds, making it possibly the fastest online CT system for testing large-scale products.

InlineCT is a fully automatic online CT detection system suitable for workpieces of different sizes and weights, such as cylinder heads, crankcases, gearboxes, and structural components.

The system includes a compact lead chamber, a linear shuttle mechanism for workpieces, a lifting/rotating unit for CT scanning, as well as a detector and an X-ray tube that can be adjusted according to testing tasks.

Through our image capture software HeiControl and variable analysis software for 3D testing, customers can analyze the data themselves. Customers can input new workpiece data and modify workpieces on-site.

VJT's standard straight pipe welding (STW) detection system is designed specifically for production environments and can provide multiple injections for each weld according to regulatory requirements. Through programmable operators and imaging solutions, the STW system can handle pipes of various diameters and thicknesses without any modification, making it an ideal choice for any pipe manufacturer. Combined with VJT's Vi3 software suite, code compliance and quality assurance have become unprecedentedly simple.