X-ray imaging acquisition and analysis software

Vi3 is a customizable software platform that supports both direct and customized X-ray imaging and control solutions

Characteristics of VI3

● Hardware control

● Image enhancement and analysis

● Archive

● Image acquisition

● Form a report

● Docking with MES system

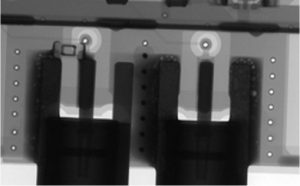

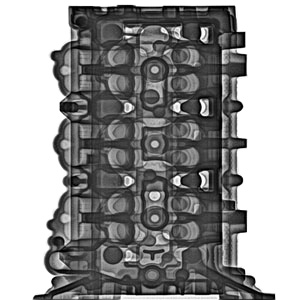

电路板的原始图像

Advanced Defect Enhancement (ADE) Filter Image

Vi3 provides fully configurable control for various aspects of the entire workflow, including motion control, image acquisition, analysis, and archiving.

Designed for scalability

The Vi3, designed for scalability, can easily interact with most industrial grade X-ray sources, detectors, and workpiece manipulation devices, thereby expanding your hardware choices.

The modular design of Vi3 allows you to easily add options and features. Vi3 has three-level password protection, making it highly secure.

Vi3 provides maximum flexibility through an open architecture that has numerous interfaces for external integration, such as PLC and database servers. It is also compatible with DICONDE and can deploy multiple data collection and review stations at the enterprise level.

If the process in your location has changed, you can adjust Vi3 to modify the workflow or processing logic. This greatly reduces the necessity of rewriting code, and even in some cases, there is no need to rewrite code. When tasks such as image capture, operator inspection, and/or ADR analysis run synchronously, the throughput of individual system artifacts can be maximized.

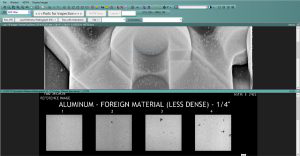

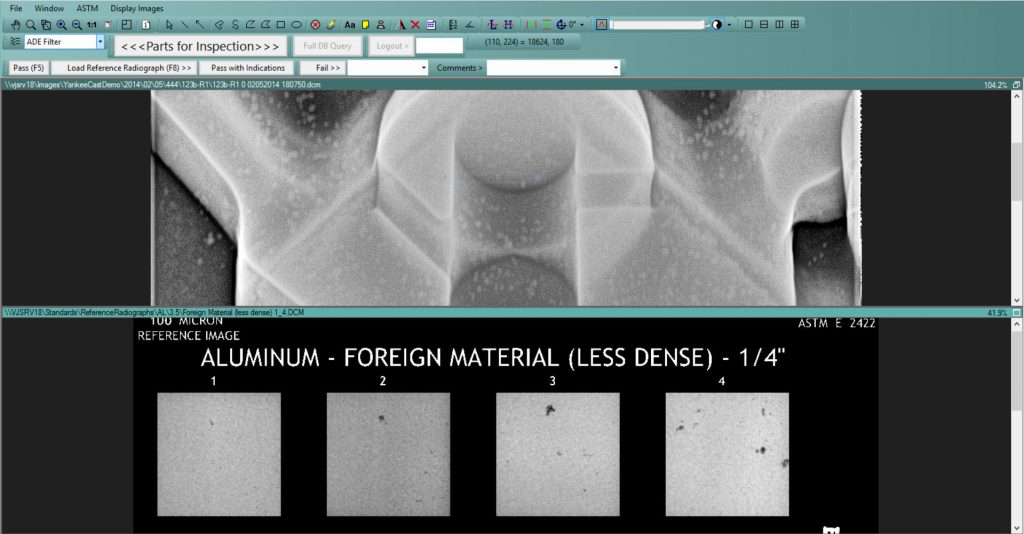

All castings with reference radiography displayed in VJT's Vi3 software:

All X-ray reference photos of castings are displayed in VJT's Vi3 software

Advanced image processing programs, such as Advanced Defect Enhancement (ADE), Automatic Defect Recognition (ADR), and other modular features, can automate the inspection process, maximizing throughput and quality. This feature helps to improve employee safety and reduce the risk to product users.

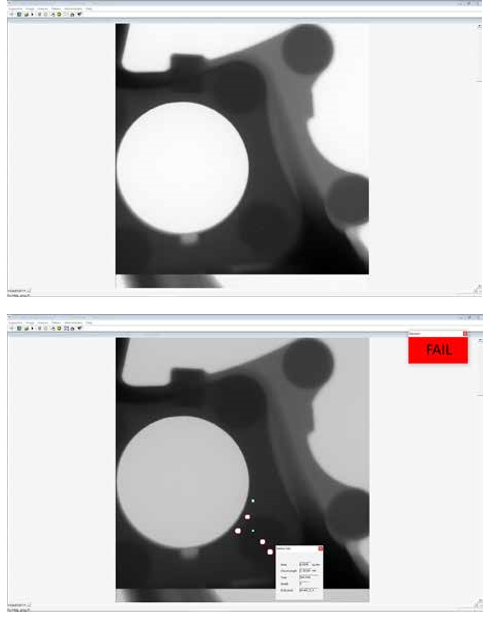

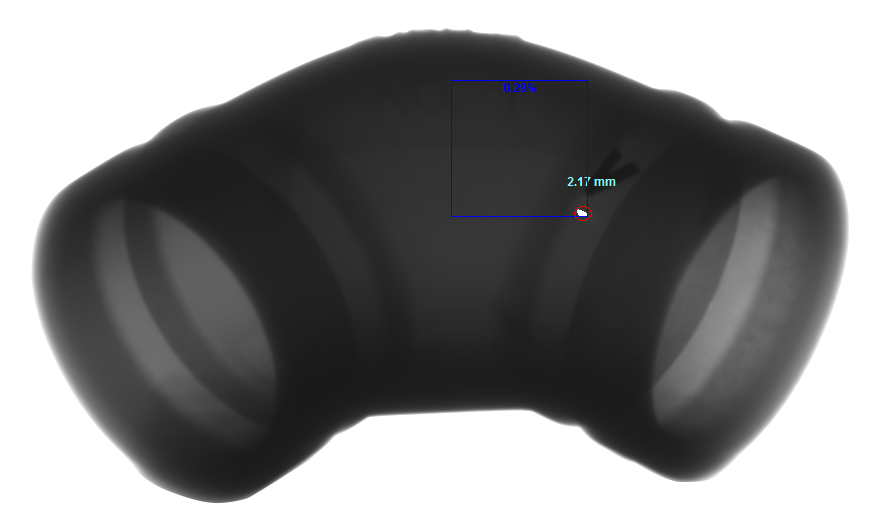

ADR automatic defect recognition

ADR Automatic Defect Recognition (ADR) includes post-processing of images for automatic detection of defects in pre programmed regions of interest. Using ADR proprietary imaging software to evaluate analog and digital radiographic data without operator intervention. The region of interest (ROI) is pre programmed using the obtained digital radiographic data. Then, the software analyzes the defects in each designated area and provides statistical process control data, which can be configured to automatically alert quality process personnel when non-conforming materials or process deviations exceed programming levels. Automatic defect recognition can improve the quality of manufacturers through repeatable and objective inspection to obtain images (top), ADR enhanced images (bottom), and improvement processes, but it can also increase productivity by reducing labor. ADR combines the X-ray examination process with machine vision. X-ray penetration products, imaging systems generate images for evaluation, machine vision automatically analyzes images and decision-making processes.

Vi3 image processing

From better data to better analysis and then to better components

Digital X-ray images can generate over 65000 grayscale levels. This presents unique challenges for data analysis and interpretation. Traditional film imaging requires shooting multiple films at different energies, film speeds, and exposure times, and interpreting them on a lightbox to display all the details of the inspected part. By contrast, our digital images capture more data, full spectrum images, to improve operations and enhancement. VJT image processing and enhancement technology can more effectively solve the problem of image cracking. Some unique modular filters developed by VJT include:

Advanced Defect Enhancement (ADE) filters:

Use proprietary algorithms to analyze individual X-ray images pixel by pixel, highlighting anomalies and defects based on surrounding areas.

原始图像/ ADE 图像

对比度和亮度拉伸/ ADE图像

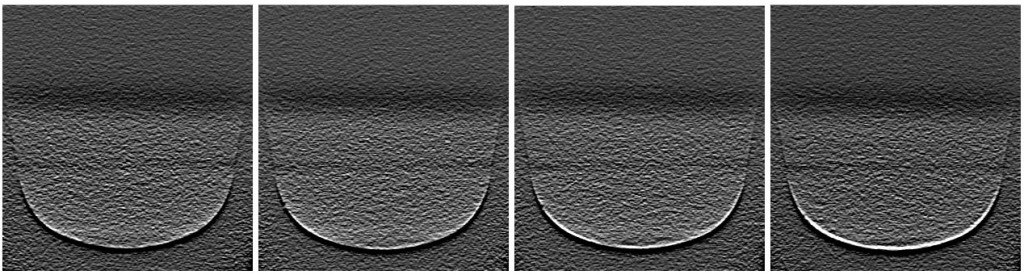

先进的降噪(ANR)过滤器:

去除通过散射、低光子计数和类似事件引入图像的噪声,而不去除图像中的微弱特征或缺陷。

原始图像 / ADE 图像

高级裂纹检测(ACD)过滤器:

适用于检测裂纹和类似裂纹状迹象的ADE过滤器的变体。

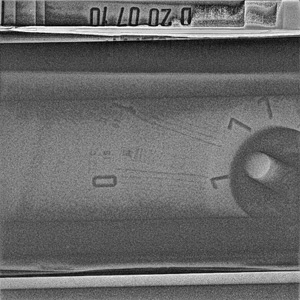

寻找弹药的基底间隙检测原始图像的/使用ACD过滤器后基底间隙检测

寻找基底间隙检测的原始图像的弹药/使用ACD过滤器基底间隙检测

X射线2.0:X射线检查的未来就是现在

我们独有的专利图像处理过滤器套件可定制和配置,以满足任何应用。从突出铸件内的气孔,到检测焊缝中的夹钨,或在婴儿食品罐中发现异物,Vi3过滤器可提高产品质量并增强产品安全性。

自动化缺陷识别(ADR)软件:

作为自动化检查的行业标准,ADR使VJT系统能够分析X射线图像,检测缺陷和判断零件(无论是操作员辅助的还是完全自动化的),使生产过程更放心。

Obtain images of pipe fittings defining regions of interest for ADR ADR identifies defects through area measurement

This is just a sample of the specialized filter provided by VJ Technologies. If you have any special requirements, please contact us.